Heavy! Anhui Tiankai jointly won the bid for the "14th Five-Year Plan" national key special project to promote the research of key core technologies in the infant matching industry

The prosperity of the country is inseparable from the support of industry, and the development of industry is inseparable from the breakthrough of key raw materials and core technologies. In order to solve the major needs of all walks of life who urgently need to solve problems through scientific and technological innovation, in the "14th Five-Year Plan" national key special project, the Ministry of Science and Technology has set up a list of "unveiling the leader" for the key core technologies that need to be broken through, paying attention to "who has the ability to unveil the list".

On December 17, 2021, in the first batch of "14th Five-Year Plan" key special plans announced by the Ministry of Science and Technology, which is also the 2021 unveiling and ministry-provincial linkage projects, 4 projects in the "Food Manufacturing and Agricultural Products Logistics Technology Support" sector have been approved, among which, the school-enterprise consortium composed of Jiangnan University, Dalian Polytechnic University, Anhui Tiankai and other units won the bid for the "Technological Innovation and Demonstration of Large-scale Preparation of New Core Ingredients for Infant Dairy Products" project.

As we all know, in addition to breast milk, infant formula is a key source of nutrition for the growth and development of infants and young children. The safe nutrition and adequate supply of infant formula is not only related to the healthy growth of each baby, but also to the future of the motherland. However, for a long time, the key ingredients required for infant formula food in China have mainly relied on imports, which not only affects the safety and stability of the industrial supply chain, but also restricts the development of related industries. Although China's population growth has slowed down in recent years, thanks to the huge population base and consumption upgrades, China's infant formula food, especially infant formula dairy market, has developed rapidly, and related industries have also developed considerably. However, due to the late start, coupled with the shortage of resources, lack of basic research, insufficient technological innovation and other factors, China's core raw materials for the production of infant formula milk powder, such as whey protein and lactoferrin, mainly rely on imports.

Although China's population growth has slowed down in recent years, thanks to the huge population base and consumption upgrades, China's infant formula food, especially infant formula dairy market, has developed rapidly, and related industries have also developed considerably. However, due to the late start, coupled with the shortage of resources, lack of basic research, insufficient technological innovation and other factors, China's core raw materials for the production of infant formula milk powder, such as whey protein and lactoferrin, mainly rely on imports.

For example, whey protein, which is the main raw material of infant formula, is a by-product of cheese processing. Due to the lack of dietary habits of eating cheese in China, coupled with the immaturity of related processing technology, whey protein is mainly imported from Europe and the United States. According to public data, China imported a total of 453,000 tons of whey in 2019, of which the European Union accounted for 45.3% and the United States accounted for 35.7%.

If the technical shortcomings of the large-scale production of core raw materials cannot be made up in time, the development of China's infant formula dairy industry is like the "barrel principle", which can never rank among the world's leading levels. Not only that, the lack of core technologies and key raw materials is also easy to make industrial development "subject to people", affecting the stability of the industrial chain, and eventually affecting tens of millions of consumers. Therefore, solving problems from the source and seeking breakthroughs is the way out of difficulties. Anhui Tiankai actively participates in the "unveiling of the leader"

Contribute to the development of China's baby matching industry

This time, it was selected as the "Technology Innovation and Demonstration of Large-scale Preparation of New Core Ingredients for Infant Dairy Products" in the 2021 "Unveiling the Leader" project, aiming at the technical preparation and demonstration production of key dairy raw materials. According to the division of labor, Anhui Tiankai mainly undertakes the preparation and demonstration production of functional milk peptides such as functional milk protein and hypoallergenic, including α-lactalbumin, milk fat globule membrane, β-casein, hydrolyzed peptide, etc., and undertakes the formulation of complete sets of technical regulations and standards for related products. So, why have these raw materials become "irreplaceable core ingredients"? Let's find out together.

α-Lactalbumin: The highest content of whey protein in breast milk, accounting for 20% of the total protein in breast milk. Infant formula is often supplemented with α-lactalbumin to bring the formula closer to the composition of breast milk.

Milk fat globule membrane: from breast milk, the same fat is also protein milk raw materials, composed of a variety of phospholipids, enzymes and mucopolysaccharides, etc., can promote neonatal brain cognitive development and enhance immunity, is a functional milk raw material that has only been successfully commercialized in recent years.

β-Casein: Casein is present in breast milk, of which β-casein is the main form present, which accounts for about 25% of the total protein in breast milk. Casein provides bioactive phosphopeptides for the human body, and can also promote the absorption of calcium in the intestines. At present, the market supply of β-casein raw materials is very limited.

Hydrolyzed peptides: Modern life is becoming more and more distant from nature, and food processing is becoming more and more delicate, resulting in more and more neonatal allergies. Hydrolyzed peptides are a milk protein source for infant formula with allergies. The quality of hydrolyzed peptides depends on the quality of the milk protein raw material and the hydrolysis technology.

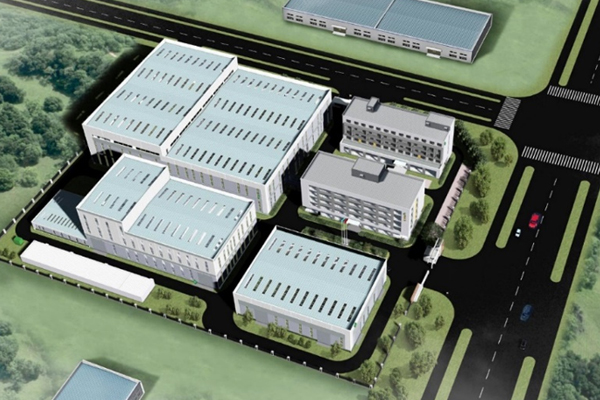

Thanks to the first batch of "14th Five-Year Plan" key special plan "Large-scale Preparation Technology Innovation and Demonstration of New Core Ingredients for Infant Dairy Products", Jiangnan University, Dalian Polytechnic University, Anhui Tiankai and other enterprises will work closely together to complement each other's advantages to jointly overcome this problem of "large-scale preparation of new core ingredients" across China's infant formula food industry chain, laying a solid foundation for ensuring the long-term safety and stability of China's baby food. (Anhui Tiankai Phase I factory layout)

(Anhui Tiankai Phase I factory layout)